Shipping is a tricky business. Unless you're shipping to your local neighborhood, you can end up...

LTL Consolidation vs. Hub and Spoke: Which One Is The Right Fit For You?

Whether you’re looking for a cost-effective solution or simply to save time, LTL freight options can increase efficiency and reduce frustration. There are numerous LTL options available, but the key is to consider the distribution model best suited to your goals and budget. One size does not fit all when it comes to LTL. Two efficient methods are LTL is consolidation and the hub and spoke method, both of which have their benefits. In learning more about the differences between consolidation and hub and spoke LTL, you can better determine which model is right for your shipping needs.

.jpg?width=1920&height=1080&name=Yellow%20Modern%20The%20Building%20Presentation%20(2).jpg)

LTL Freight Consolidation

Consolidating shipments is the process by which multiple smaller shipments heading to a similar location are consolidated at a warehouse and then loaded onto a single full truckload, and transported to their destination. Multiple shippers or companies can then use one truck to transport their goods, at a lower cost than a full shipment. Once the freight reached a consolidation center, the freight is sorted and separated to be shipped into a full truckload, with the truck making multiple stops along the way.

Benefits of Consolidation

Cost Saving

Consolidating shipments allows shippers to save money on shipping costs, as they are only paying for a portion of truck space used. Consolidation essentially allows shippers the advantage of getting FTL service but at LTL price points. As the freight volume is higher by combining shipments heading to the same region, the transport rate is lower. In the cases where carriers are charging per mile, this can be a cost effective option to ensure a better fee for the shipper, while still getting their goods where they need to go.

Reduces Risk Of Damage

As shippers send out consolidated shipments, there is less of a chance of damage to the cargo because there are fewer hands handling the freight. Once consolidated freight is loaded onto the transport truck, it goes to its destination without being unloaded or loaded again along the way, thereby reducing risk.

Convenience

The more steps there are in the transport process, the more likely there are risks of delay. In shipping consolidated, there is less stress to manage, due to the limited touch points or steps the cargo will take en route. There is a speedier loading or docking process, since the carrier is responsible for the freight in their possession, which can improve loading and unloading time, and lead to faster moving freight.

Sellers can manage their entire distribution chain themselves or through logistics partners, which ensures more control over their schedule and production timelines. For those who need to fulfill demand, they can integrate customer needs into their consolidation plan. A consistent shipping schedule ensures lack of delays or errors in the process, and ensures quicker delivery times.

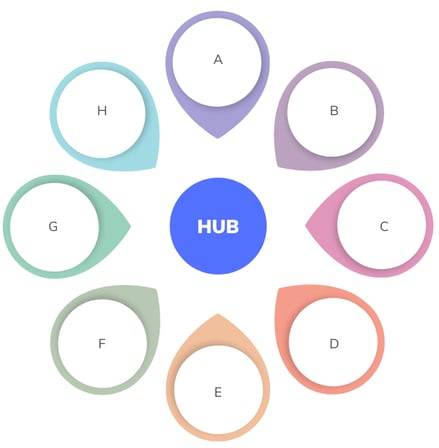

Hub and Spoke

The hub and spoke distribution model is a method relying on one central location, known as the hub, and numerous local terminals or warehouses, known as spokes, so that goods can be transported. Freight ships from one place to another, and this transfer process carries on until the freight gets to its destination.

The hub and spoke distribution model is a method relying on one central location, known as the hub, and numerous local terminals or warehouses, known as spokes, so that goods can be transported. Freight ships from one place to another, and this transfer process carries on until the freight gets to its destination.

Carriers use numerous shipping centers or hubs, at which freight can be organized and placed onto truck for delivery. This process ensures that goods are stocked in one central location, the hub, and then the various distribution or shipping centers will be assigned for the delivery process. All shipments can potentially be sent through multiple hubs at a regional or national level, before its final destination. Merchants control their inventory centrally, allowing them to source products from affordable suppliers, and then deliver goods from local spokes.

Benefits of Hub and Spoke

Cost-Effective

The centralized model allows shippers or merchants to take advantage of better rates for their inventory or supply, as they are sourcing products to one hub or centralized point. This centralized model allows small or medium sized shippers to negotiate for better transport rates, as they are able to combine multiple LTL shipments into one large shipment, to be distributed throughout the network. Carriers are not wasting fuel or driver resources on partially loaded trucks, rather there is a full truck ready to transport from the hub to various locations within the network.

Efficiency

Carriers are able to transport more efficiently using the hub and spoke model, as freight is stored at a hub and organized for transport onto one truck ready to make delivery. This means shipments are consistently on the move and not stored in warehouses for long, as there are multiple smaller deliveries made. The hub also allows the gathering of multiple LTL shipments throughout a day and then enables transport of one full truck, when it is ready, resulting in more economical transport for carriers, saving in fuel costs.

While shipping times may take longer in this mode, the pickup speed is faster, because the various spokes or distribution locations are usually within shorter regional distances from the hub. Because freight moves along the spokes, there is potential for optimal planning of delivery routes, knowing the traffic times and shortest routes possible.

Greater Visibility and Control

Shippers are able to track shipments as they arrive and depart from a hub, allowing for greater awareness of where the cargo is at all times and ability to address any issues early on. Due to the fact that shipments are picked up from one designated hub, it is also easier to maintain stock and ensure supplies are consistent in a particular area. The method also allows for better resource allocation, as one can note if there is high demand in a specific area as opposed to another, and redirect resources to the areas which need it more.

-3.png?width=1200&height=400&name=Ivory%20Elegant%20Summer%20Fashion%20Blog%20Banner%20(10)-3.png)

What Are The Challenges of These Methods?

The hub and spoke method results in higher inventory costs, as inventory will be placed or shifted between multiple smaller locations. It is also important to consider the shipping speed as a disadvantage, as the response times may be lower due to the distance between hub and each of the spokes. Products need to be delivered from the hub to the spoke and then to client, which can be time consuming in case of needing to move shipments from hub to spoke and then to client, resulting in a longer delivery time. It is also critical to note that many hands are handling the freight due to the frequent loading and unloading that the cargo is undergoing, which can increase risk of damage or loss.

LTL consolidated shipments may be quicker, but there is lack of flexibility in pickup or delivery times, which makes scheduling difficult. There is a need for advance planning in order for carriers to be able to take on the size of the freight, as it is often larger than the usual LTL shipment. As a result, most carriers have limited capability of offering consolidated LTL options, and usually they have limits to them. It is also challenging to find a reliable logistics provider who can perform LTL consolidation well, and communicate effectively, due to the complexity of scheduling multiple shipments and various shippers or carriers involved.

When to Use LTL Consolidation vs. Hub and Spoke

If you are considering using LTL consolidation, you will likely benefit if you are shipping partial loads, about 5-20 pallets, often and on a consistent basis. If you have one shipment or an inconsistent shipping schedule, then hub and spoke may benefit you. Smaller or more dense shipments can benefit from hub and spoke, but may take longer to deliver. In the case of timing, for time sensitive delivery, consolidation is the better option. High value items or shipping fragile freight will likely be better off using consolidated freight, as there are added requirements for the shipment.

When it comes to choice, company size and customer needs matter. The choice really depends on what you're shipping, where, and the budget of your company. There is no one size fits all. The next time you’re deciding between a consolidated and hub-and-spoke distribution model, remember that each has its pros and cons. Make sure to choose the best fit for your company, and the needs or expectations of your customers.

.png?height=200&name=Orange%20Modern%20Minimal%20Blog%20Writing%20YouTube%20Thumbnail%20(5).png)

.jpg?height=200&name=White%20Minimalist%20Aesthetic%20Magazine%20Photography%20Portfolio%20Presentation%20169%20(21).jpg)

.jpg?height=200&name=Blue%20Illustrated%20Dots%20Hosting%20Provider%20Presentation%20(1).jpg)